Devashish Enterprise is not only the authorized suppliers but also a expert Installers for the world renowned Johnson V Wire Filter Screen conforming to BIS 8110: 2000 on PAN INDIA basis and have several large prestigious installations to our credit. Our knowledge and expertise in the field of Rain Water Harvesting System has made us a leading player committed to provide the best available technology / solutions to discerning client . Although Johnson V Wire Filter Screen conforming to BIS 8110: 2000 are long lasting due to their superior design / material of construction resulting in trouble free service for years to come. But we do undertake AMCs for their proper maintenance. Our one point solution for all RWH requirements has brought us several laurels and repeat businesses.

WTP & STP:

For larger lay outs such as townships, colonies besides RWH System, WTP & STP are also integral part of the RWH System as the water collected from surfaced runoff is contaminated thereby making it unfit for consumption. We therefore also supply compatible range of WTP & STP with exacting standards for specific requirements.

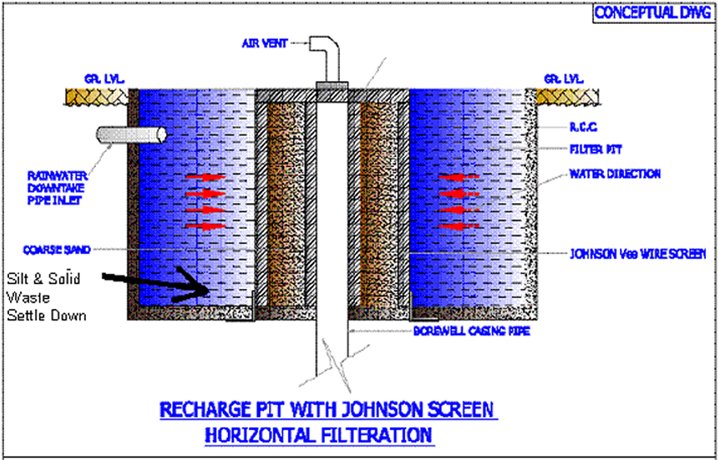

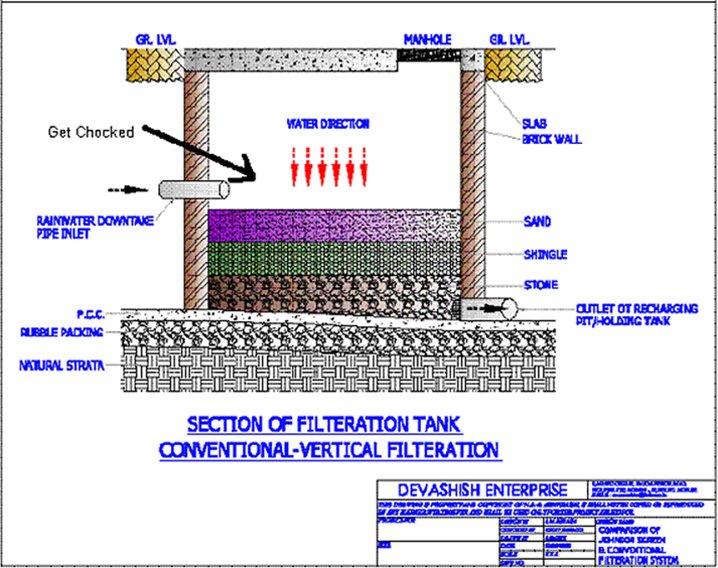

BETWEEN CONVENTIONAL FILTER PIT WITH JOHNSON SCREEN SYSTEM

|

JOHNSON DESIGN |

CONVENTIONAL DESIGN |

|

Continuous Slots |

Special design gives continuous slot opening across the periphery and length of screen. |

Slots are scattered |

|

Non Clogging Slots |

V-shape wire which gives inwardly widening V-shape slots. This shape does not give space for any sand particle to get stuck inside the slot and hence these screens are non clogging. Hence the efficiency of tube well is not reduced over number of years due to clogging. |

Highly susceptible to clogging due to vertically settling impurities in water and floating matters which reduces permeability of filter media |

|

Very Large % Open Area |

Design gives continuous slot and hence the % open area for water to enter is more than 2 times that of conventional slotted pipes of same size and slot opening. This allows more water to enter at much lesser frictional head loss and the efficiency of tube well is improved appreciably. |

Less open area |

|

Better Sand Filtration |

Due to specialized manufacturing process, wide range of slot opening is available down to 0.15 mm to allow proper slot selection depending upon the size of sand in particular area. This gives better sand control and reduced pump maintenance and longer bore well life. |

Precise slot selection is not possible depending on the size of sand in particular area |

|

Cleaning & Maintenance |

Cleaning Maintenance is very easy and fast.

|

Total layers of gravel and sand to be removed and may be required frequently during the time of maintenance.

Cleaning procedure is time consuming, laborious and costly. Very difficult to maintain during the season.

|

|

Sustenance of Recharge process |

Raw water enters horizontally into the screen assembly and it begins from the bottom of the pit hence all the impurities will be settled at bottom first. Due to above phenomena pit will remain open from the top and recharge process will be continued more than the conventional system.

|

As the top layer gets chocked, the rate of percolation of water to the well will go down rapidly. |

|

Easy Monitoring & Transparency of Filter Pit

|

The operating condition of the filter pit can be easily monitored so that suitable precautions can be taken if necessary. |

Once the pit filled with gravels and other media, then it will not be possible to visualize the working process so no advance actions can be taken to rectify. |